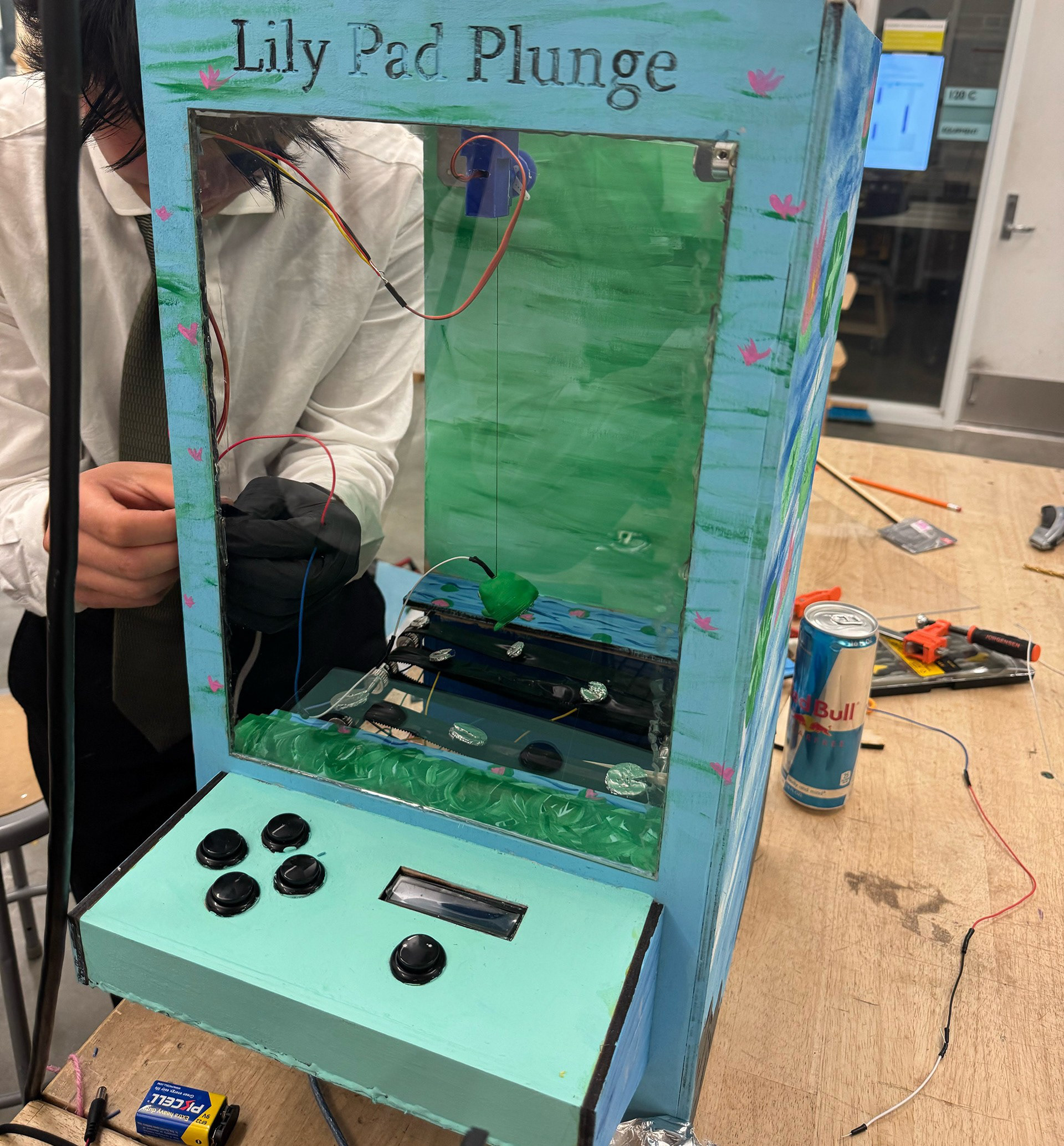

What is Lily Pad Plunge?

Lily Pad Plunge is a new twist to arcade gaming that presents a variety of challenges to players. The game has up, down, left, right, and drop button controls to move and drop the frog onto moving lilypads below. The goal of the game is to drop the frog onto as many pads before the allowed time passes, with smaller pads netting more points.

My role in Lily Pad Plunge

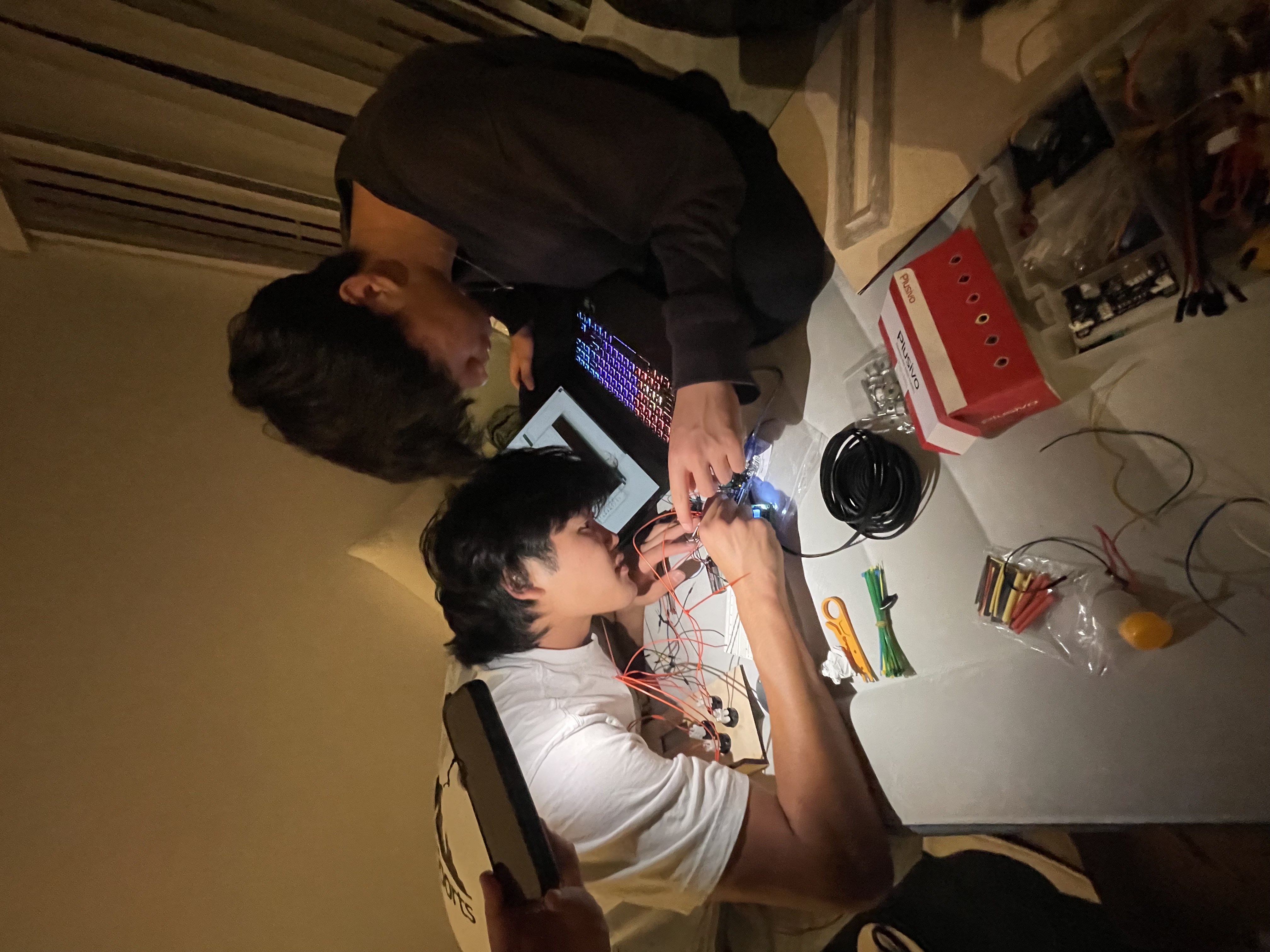

As the Electrical and Systems Integration Engineer of our team, I designed the functional and power efficient circuitry, developed the embedded framework, and worked with the mechanical and software teams to fully integrate the game to work with seamless control. This project was not only a great test our technical ability, but a great opportunity to create a remarkable product with my amazing team! I can't imagine this coming to fruition without them.

Electrical Design

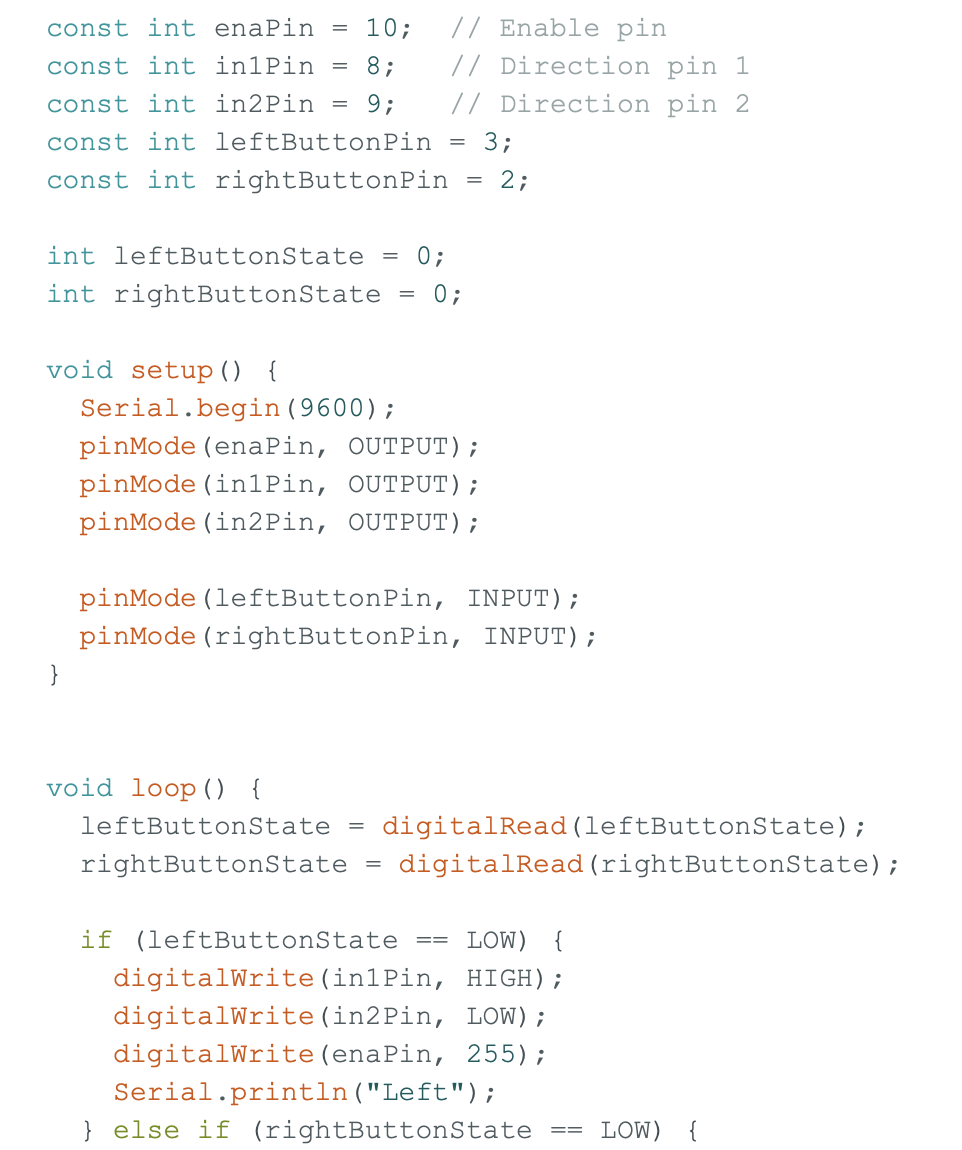

The major challenges in the electrical design lie in the sheer amount of components and parts that require both power and programming. The system includes servo motors, sensors, buttons, and an LCD, which all also needed to be programmed to respond based on user input. The power distribution was designed first through simulation, then integrated with embedded needs. The microcontroller (Arduino Mega) was programmed in C++ and directed gantry control, frog release, lily pad motion, score count/timer, and display settings. In our final product, we succesfully optimized the power distribution such that the entire device could operate reliably powered with just 2 9V batteries, while ensuring all mechanical components responded accurately and consistently. This was achieved through utilizing buck converters and capacitors for stable power conversion.

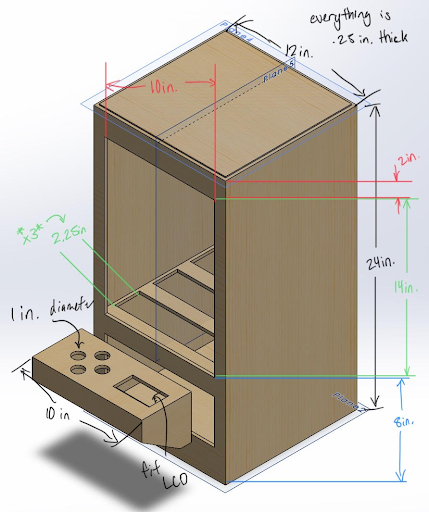

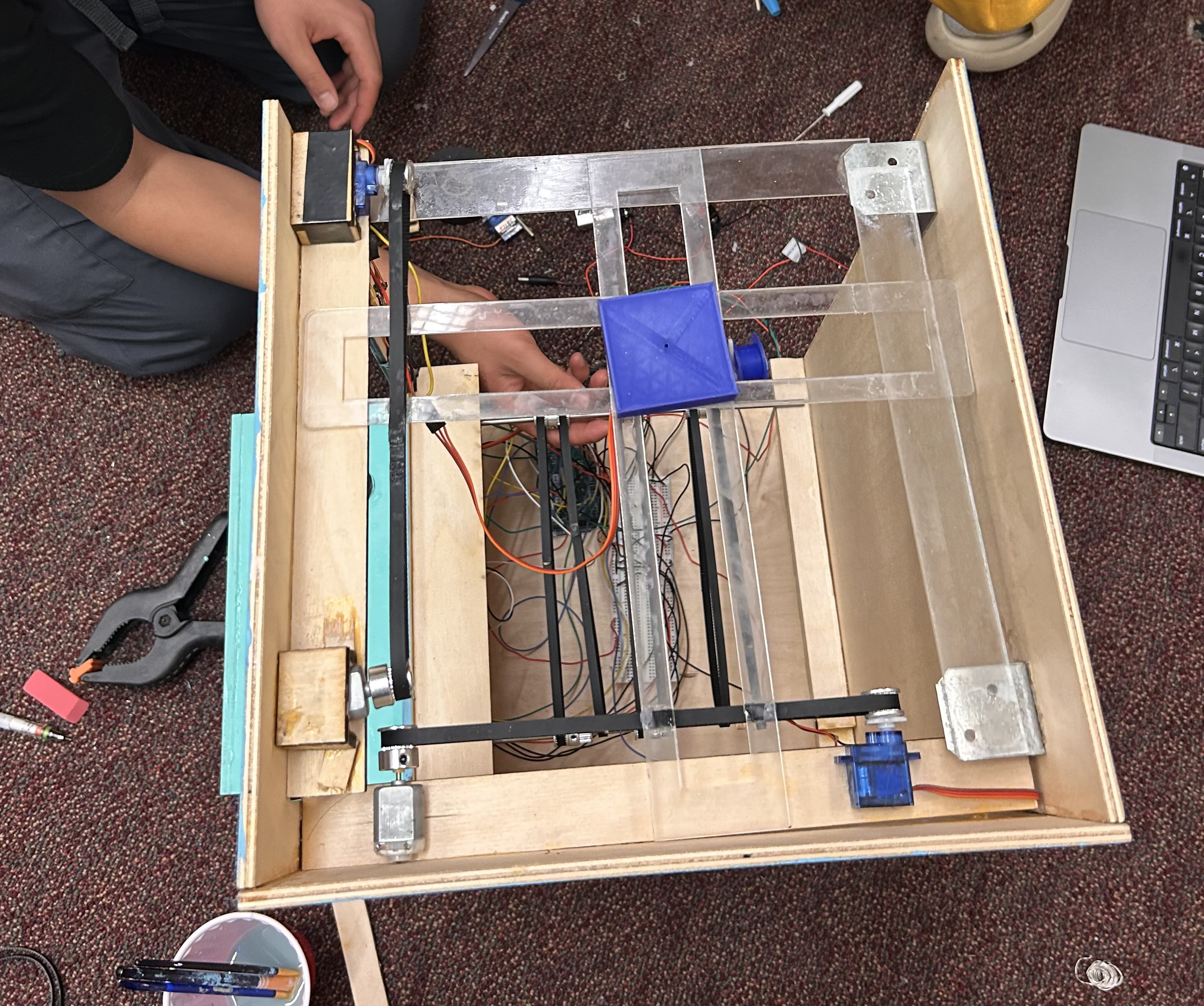

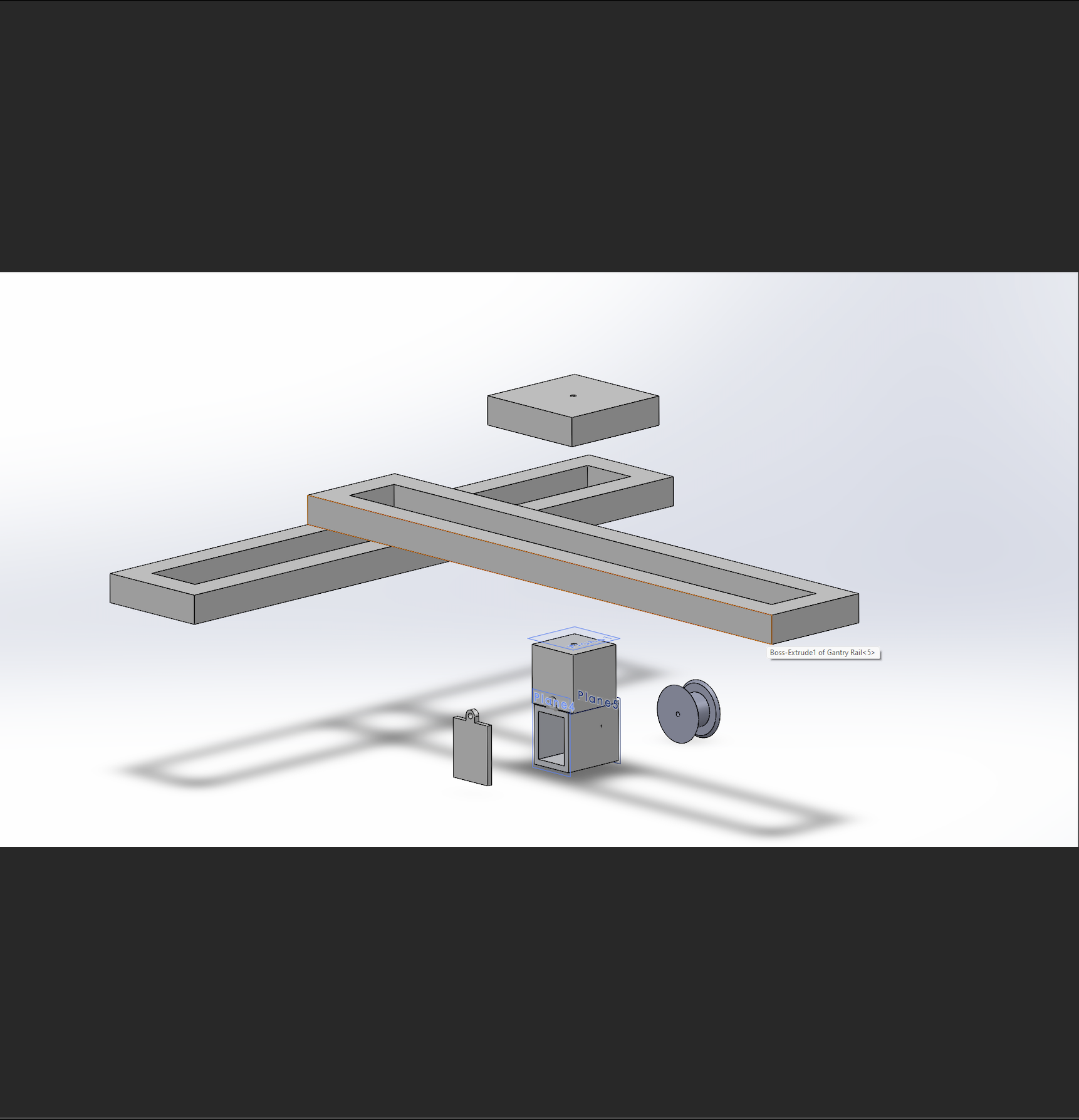

Mechanical Design

We began by designing a gantry system capable of smooth movement across three axes of motion. The gantry features a cross-shaped structure with its sides attached to belts, enabling precise and fluid movement. Next, we designed the machine's frame: a simple box structure that accommodates the electrical components and conveyor belts. Our arcade machine is scaled down from traditional sizes, making it more compact and portable for home use and travel.

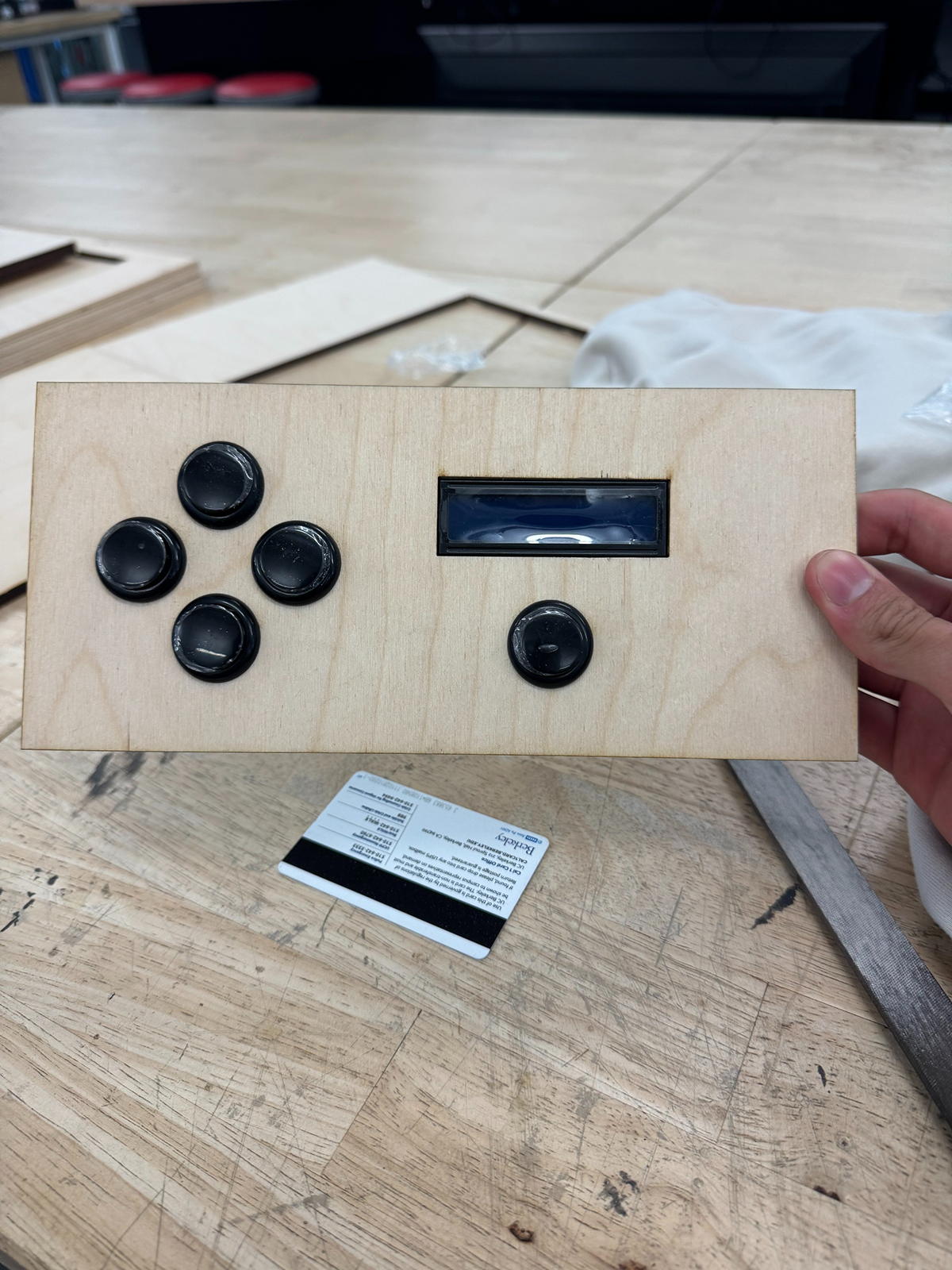

The frame is constructed from 1/4" plywood with dimensions of 12" (length) x 12" (width) x 24" (height). Finally, we created the console housing in CAD, designed to hold the control buttons for maneuvering the gantry system and an LCD screen to display real-time game progress. Beneath the buttons and LCD, we allocated space for the electrical components that operate these controls. The CAD design incorporated interference fits to securely hold the buttons and LCD in place, eliminating the need for adhesives that could potentially damage the components, an approach that proved successful.

Software Design

The button inputs controls for frog movement along x and y axes uses a boolean state to toggle between game start and drop actions. The frog's position is tracked with coordinate variables and boundaries to prevent movement beyond set limits.

The scoring system updates a points variable based on lily pad size, using calibration variables set at game start. A dropCount variable tracks attempts, switching a gameState variable to “game over” after three drops. The score variable updates continuously on the LCD, and input processing is disabled when the gameState indicates the game has ended. The program also accounts for end to end user interactions with the LCD feedback/button inputs to start and end the game.